A space to engineer the future

William A. Demmer Engineering Center gives student groups hands-on learning experience

A space to engineer the future

William A. Demmer Engineering Center gives student groups hands-on learning experience

November 10, 2023Life in the 10,000-square-foot William A. Demmer Engineering Center moves fast as several MSU engineering student organizations occupy the new space at Farm Lane and Mount Hope Road.

If it weren’t for the generosity of longtime MSU supporters Bill and Linda Demmer, many of these groups would still be working in spaces scattered across campus. Now they are focused on building community, learning from each other and developing valuable job skills while they specialize in everything from electric, solar and off-road racing to human-powered vehicles and mobility-inspired exoskeletons.

“The William A. Demmer Engineering Center has given everyone a home,” MSU Solar Racing Team president Prerana Gunda says.

The dedication for the $4 million facility took place in October 2022 and opened to hundreds of students in August 2023. Students now have on-campus access to a collaborative environment where they are involved in building governance, starting with the establishment of safety rules, building access protocols and project management.

Students meet with MSU College of Engineering staff and faculty several times per month to provide status updates and progress reports: all valuable preparation for future careers.

"The MSU facilities team, working with the students and their needs, have created an outstanding facility for engineering teams to work on projects," says William (Bill) Demmer. "My wife Linda and I are proud to be connected to my school in such a meaningful way. It is a real pleasure to be associated with an effort designed to inspire both world-class learning and teamwork."

MSU College of Engineering Dean Leo Kempel is grateful for Bill and Linda Demmer’s vision for the facility and support.

“This facility offers expanded opportunities for our students to explore their interests in a hands-on manner, outside the classroom,” Kempel says. “In doing so, they are learning much more about how the business community gets projects completed and how to compete at the highest level among our peers."

More experienced teams pass on their knowledge to newer teams, and all teams leverage the space for recruiting new members. Students bounce ideas off each other, share resources and get each other prepared for competitions against other universities and colleges.

MSU Rocketry recently gave some extra carbon fiber to the Formula Racing Team in exchange for some tips on how to make its new rocket tube stronger and lighter.

“We’re one university,” says MSU Rocketry Team co-chief engineer Robert Dessy, a mechanical engineering junior. “We’re not competing against each other.”

The William A. Demmer Engineering Center offers students full access to a flexible workspace where walls and barriers are kept to a minimum. A design center inside the facility features a bank of computers and equipment, including plotters and 3D printers as well as designated spaces for machinery, tooling, worktables and benches, welding areas, computers, meeting rooms, a body shop area, storage crates and even fly zones for rockets and drones.

Student groups working at the facility treat their organizations like small businesses. There are strategies to develop, travel budgets to manage and corporate sponsor relationships to cultivate and maintain.

Major employers like Tesla, Ford, General Motors, Hyundai and Johnson & Johnson are drawn to the students who are actively involved and leading projects at the facility. Many students have already been contacted and hired for internships and full-time jobs.

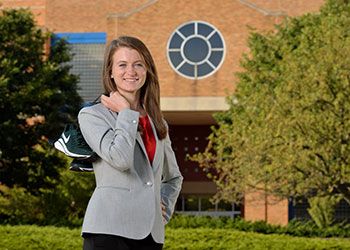

This is the best learning atmosphere as students prepare for engineering careers, says Alice Shirley, a Michigan State University data science sophomore.

Shirley, from Metro Detroit, didn’t know much about cars a few years ago. Now as the MSU Formula Racing Team’s cockpit lead, she is responsible for designing the 500-pound, $250,000 student-crafted vehicle’s seat, steering wheel and pedal systems. The vehicle can travel 85 miles per hour and will convert to electric power next year.

“When I come to the center, I can see how the skills I learn here apply outside the classroom,” Shirley says. “Every day is exciting and new.”