Detroit Roots Run Deep for Research Leader

Support world-class research that is changing Michigan, the nation, and world

Detroit Roots Run Deep for Research Leader

Support world-class research that is changing Michigan, the nation, and world

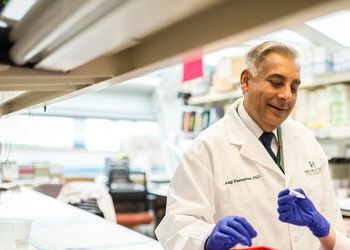

August 14, 2015Solving manufacturing problems has been a part of Lawrence Drzal’s life from the start.

You could even say it’s in his DNA.

Growing up in Detroit as the son of an auto manufacturing father, Drzal—now a university distinguished professor of Chemical Engineering and Materials Science at Michigan State University’s College of Engineering—has established himself as an experienced, nationally-recognized leader in the area of materials science.

Drzal serves as director of the Composite Materials and Structures Center, an MSU center dedicated to the production of fiber-reinforced polymer materials. He is also director of the Michigan Center of Excellence, and in January 2015, President Obama announced MSU as a partner in newly-formed Institute for Advanced Composites Manufacturing Innovation (IACMI).

“I’ve had unique experiences that illustrate connections one can make over a long period of time, sometimes serendipitously,” Drzal said.

All roads lead to MSU

Drzal’s path as an undergraduate at the University of Detroit led him to three years with auto supplier Sheller-Globe and then to Ford, where he worked on the process of making tempered and strengthened glass for vehicles.

“Although my co-op experiences were in materials R&D [research and development] related to autos, I worked on problems related to manufacturing these materials,” Drzal said. “I developed my interest in and connection to polymers and plastics because of these experiences.”

After working for ten years as a research scientist in the Air Force’s Materials Laboratory, Drzal’s appetite for research grew, along with his success in the lab. When the opportunity to take the next step in his career presented itself, Drzal realized he could go anywhere—but MSU’s land-grant mission was what ultimately attracted him back to Michigan.

“I appreciated the idea that my work could ultimately impact the wellbeing of people everywhere,” Drzal added. “That, combined with top faculty and the ability to work across disciplines made MSU the ideal place for me.”

Drzal’s mission? To make durable goods like windmill blades and automobiles perform better, and at a lower cost using composite materials.

Composite materials are as strong as steel and very light weight. For the auto industry, the materials mean increased fuel-efficiency and safer vehicles. Composites can also be used for renewable energy purposes; there is also an added benefit of job creation in Michigan, since more vehicles can be produced in a shorter amount of time.

The ‘center’ of it all

Managing multiple centers is an environment Drzal has thrived in, which is due to a couple factors.

“If you don’t have a ‘center’ environment where you can get enhanced collaboration between faculty and graduate students working on these problems, you’re not going to make advances,” Drzal said. “Michigan State has been an extremely good environment, with its low barriers to collaboration, it has very good investment in areas that will be beneficial certainly to people in the state, but also nationally and internationally.”

Continued investment in research like Drzal’s is the key to advancing materials science, and world-class centers and institutes only increase MSU’s ability to attract leaders like him, as well as top graduate students.

Learn more about endowed faculty positions.

Author: Sarah Wardell